charpy impact test image|charpy impact chart : store In 1896, S. B. Russell introduced the idea of residual fracture energy and devised a pendulum fracture test. Russell's initial tests measured un-notched samples. In 1897, Frémont . See more Filename D:\EAC RIPS\Keiko Matsui - Euphoria\10 - Blue Water.wav Peak level 96.7 % Extraction speed 1.7 X Track quality 99.9 % Test CRC 518F9925 Copy CRC 518F9925 Accurately ripped (confidence 2) [540CC465] (AR v2) Copy OK Track 11 Filename D:\EAC RIPS\Keiko Matsui - Euphoria\11 - Euphoria.wav Peak level 96.3 % Extraction speed .

{plog:ftitle_list}

Resultado da 24 de nov. de 2012 · Luiz Augusto Castrillon de Aquino depôs na primeira audiência com os 22 réus do caso (apenas um deles não compareceu). .

charpy impact test sample

scuffing machine

charpy impact test procedure

In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it . See moreIn 1896, S. B. Russell introduced the idea of residual fracture energy and devised a pendulum fracture test. Russell's initial tests measured un-notched samples. In 1897, Frémont . See moreThe quantitative result of the impact tests the energy needed to fracture a material and can be used to measure the toughness of the material. There is a connection to the yield strength but it cannot be expressed by a standard formula. Also, the . See more

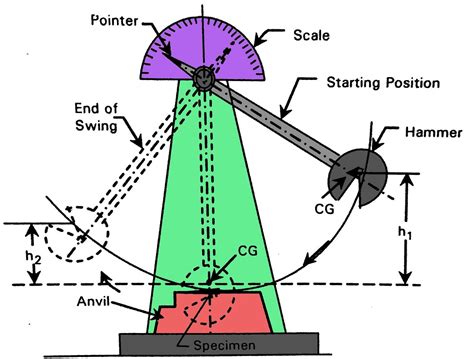

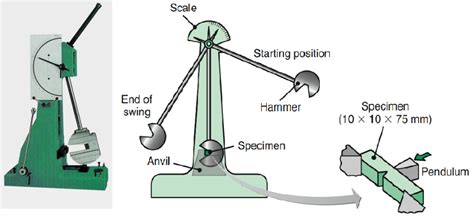

According to ASTM A370, the standard specimen size for Charpy impact testing is 10 mm × 10 mm × 55 mm. Subsize specimen sizes are: . See more• Izod impact strength test• Brittle• Impact force See moreThe apparatus consists of a pendulum of known mass and length that is dropped from a known height to impact a notched specimen of material. The energy transferred to the . See more

The qualitative results of the impact test can be used to determine the ductility of a material. If the material breaks on a flat plane, the fracture was brittle, and if the material breaks with . See moreThe impact energy of low-strength metals that do not show a change of fracture mode with temperature, is usually high and insensitive to temperature. For these reasons, impact tests . See more

i scratched my toilet bowl

This makes Charpy testing a popular choice for assessing the toughness of metals like steel, as well as polymers, composites, and ceramics. Here’s how the process works: The test .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its . A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after impact.This page introduces the Charpy impact test principle and methods; as well as evaluation methods, test piece standards, differences from the Izod impact strength test, and methods for measurement of the fracture surface.

The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This . Charpy testing is a method for determining the relative impact strength of metals. It is also known as the Charpy V notch test. This testing method was developed in the 1940s by S.B. Russell and G. Charpy. Image .The Charpy test is a standardized procedure designed to measure the energy absorbed by a material during a sudden impact load. This evaluation method assesses the material's .

The Charpy impact test (Charpy V-notch test) is used to measure the toughness of materials under impact load at different temperatures! Test setup and test procedure. In the Charpy impact test, a notched specimen is .

Charpy impact testing determines the impact energy of materials. The test procedure, the application of charpy testing, factors affecting impact energy, the ductile to brittle transition are all covered.

A Charpy test determines the impact toughness of metal samples by striking them with a swinging mass. The traditional test method requires measuring the difference between the height of the striker before and after impact. An instrumented striker, on the other hand, has force .

In a Charpy impact test, three key measurements are typically made: total absorbed energy, lateral expansion, and percent shear fracture area. At present, the measurement of absorbed energy and lateral . Digital image analysis for shear fracture area is shown to be accurate, precise, and easy to use on a routine basis. Recommendations for .

The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the requirements for specimens, for the performance of the test, for result reports and for testing machines, i.e., pendulum impact testers at ambient . Abstract The NIST Charpy Machine Verification Program supplies ASTM E23 certified Charpy reference specimens to customers all over the world since 1989, when the program was transferred from the US Army at Watertown Arsenal, Massachusetts. A decade before an iceberg shattered the hull plates of the Titanic and half a century before a plague of brittle fractures started sinking Liberty ships during World War II, scientists in the United States and France had devised a novel, and strikingly simple, method for measuring the way metal reacts to impact.. Today, that method, with some upgrades and . Aluminum alloy wheels are used worldwide in both the warmest and coldest temperatures. This study was conducted to investigate the impact resistance of aluminum alloy wheels produced by the low-pressure die casting process in real-life conditions. The V-notched Charpy impact test specimens were extracted from T6 heat-treated A356 aluminum alloy .

Drop Weight Impact Testers. Instron Drop Towers are used to develop, fine tune, and validate material models. The new 9400 Series produces reliable, repeatable results whether you are testing materials and components before production to improve product acceptance or testing during production to ensure continuous improvement. More Info

This work has been released into the public domain by its author, I, Matthias Doell.This applies worldwide. In some countries this may not be legally possible; if so: I, Matthias Doell grants anyone the right to use this work for any purpose, without any conditions, unless such conditions are required by law.To determine the material resistance to impact from a swinging pendulum. Apparatus Required. Charpy testing machine, a rod of mild steel and a rod of carbonate steel. Charpy Test Specimens. Charpy test specimens normally measure 55x10x10mm and have a notch machined across one of the larger faces. The notches may be :The Charpy impact specimens of each material are immersed in a bath for 10 minu tes to reach thermal equilibrium at five separate temperatures ranging from 110oF (-79oC) to 212-oF (100oC). The specimens are quickly transferred to the Charpy testing machine, fractured, and the impact energy is measured. After

The Charpy impact test (CVN) is still the most widely used test for evaluating the absorbed energy and transition temperature of line-pipe steels because of its simple testing method and fewer constraints on specimens [4,5,6].Tested pipes are widely recognized to have sufficient strength and toughness to be applied to very low-temperature pipelines [].measuring impact energy are: Charpy Test and Izod Test.Charpy impact test is a low-cost and reliable test method, which is commonly required by the construction codes for fracture critical structures such as bridges and pressure vessels. Charpy impact test was developed in the 1960's as a method of determining the relative impact strength of .

The Charpy impact test, which makes use of the potential energy of a falling pendulum to fracture specimens at high strain rates, has also been frequently employed for characterization of cementitious composites. Demonstrated by Russell [22] and Charpy [23] near the turn of the 20th century and standardized

Chapter 2 – Effects of Processing and Temperature on Charpy Impact Toughness in Metallic Glasses and Metallic Glass Matrix Composites Introduction to Charpy Testing Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM

According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significant

Find Impact Test stock images in HD and millions of other royalty-free stock photos, 3D objects, illustrations and vectors in the Shutterstock collection. Thousands of new, high-quality pictures added every day. . Charpy Impact .Other articles where Charpy impact test is discussed: metallurgy: Testing mechanical properties: .test of toughness is the Charpy test, which employs a small bar of a metal with a V-shaped groove cut on one side. A large hammer is swung so as to strike the bar on the side opposite the groove. The energy absorbed in driving the hammer through the bar.The Charpy impact test, also known as the Charpy V-notch test, is a high strain-rate test that involves striking a standard notched specimen with a controlled weight pendulum swung from a set height. The impact test helps measure the amount .

An impact test consists of a striker hitting the test specimen to transfer a large force in a short time.You can use a drop tower or a pendulum tester to achieve such large forces.. A striker is dropped vertically from a height for a drop tower test and uses gravity to achieve the necessary impact energy. Similarly, in a pendulum test, the striker is fixed to an arm that swings like a .The document provides details on conducting a Charpy impact test to evaluate the mechanical properties of materials. It describes the theory behind impact testing, the key equipment used - including specimens, a Vernier caliper, Instron Ceast 9050 impact tester, and microscope. It also outlines the step-by-step procedure for setting up and performing an impact test, which . The Charpy impact test is a high strain-rate test to find the impact toughness of a material. In the Charpy impact test, a standard notched specimen is struck by a controlled weight pendulum swung from a predefined height. . Fig. 1 below provides an image of a typical Charpy impact test machine. Pendulum impact testers are highly versatile .Find Impact Testing stock images in HD and millions of other royalty-free stock photos, illustrations and vectors in the Shutterstock collection. Thousands of new, high-quality pictures added every day. . Charpy Impact test simple 1. Save. Crash test with 3d rendering dummy hit with air bag . Save. Sure! "I collected a water sample from the .

Basic principle and practical procedure of the Charpy impact test - Testing machine, test specimen - Basic principle, impact energy measurement - Temperat.Miniature Charpy pendulum impact testing (ASTM E2248) Beverage can impact testing. Options. The impact test equipment can be provided with several options: Optical encoder for velocity and energy measurement (pendulum machines only) . Image analysis system for percent shear determination. The Charpy impact test is used to identify the transition between ductility and brittleness. The percentages of ductile and brittle fractures in steel can be evaluated based on each fracture area, which is presently determined by an analyzer with the naked eye. . {A New Fracture Analysis Technique for Charpy Impact Test Using Image Processing .

The three most popular types of tests for a single impact are Charpy V, Izod and tensile impact. These three tests determine essentially the same characteristics of the material, but differ in the orientation of the test specimen, which causes the specimen to strain in different directions and involves a known weight released from a known .

WEBLei & Ordem: Unidade de Vítimas Especiais. Temporada 18. Como comandante da Unidade de Vítimas Especiais do Depto. De Polícia de NY, a Sgt. Olívia Benson (a .

charpy impact test image|charpy impact chart